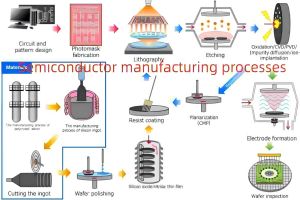

In modern semiconductor manufacturing processes, the purity of materials is critical to the performance of the final product. As China's leading high-purity crystalline boron powder manufacturer, UrbanMines Tech. Limited, relying on its technological advantages, is committed to the research and development and production of high-purity boron powder that meets the needs of the semiconductor industry, among which 6N purity crystalline boron powder is particularly prominent. Boron doping technology plays a vital role in the production of semiconductor silicon ingots, which not only improves the electrical properties of silicon materials, but also promotes more efficient and more precise chip manufacturing. Today, we will take a deep look at the application, effect, and competitiveness of 6N purity crystalline boron powder in the semiconductor industry in China and the global market.

1. Application principle and effect of 6N purity crystalline boron powder in silicon ingot production

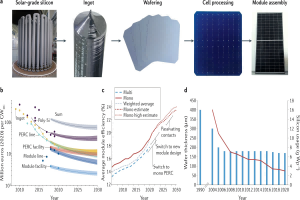

Silicon (Si), as the basic material of the semiconductor industry, is widely used in integrated circuits (ICs) and solar cells. In order to improve the conductivity of silicon, it is often necessary to change its electrical properties by doping with other elements. Boron (B) is one of the most commonly used doping elements. It can effectively adjust the conductivity of silicon and control the p-type (positive) semiconductor properties of silicon materials. The boron doping process usually occurs during the growth of silicon ingots. The combination of boron atoms and silicon crystals can form ideal electrical properties in silicon crystals.

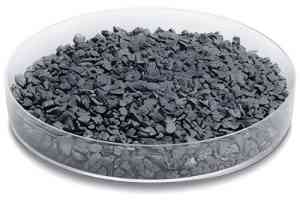

As a doping source, 6N (99.999999%) pure crystalline boron powder has extremely high purity and stability, which can ensure that no impurities are introduced during the silicon ingot production process to avoid affecting the quality of crystal growth. High-purity boron powder can accurately control the doping concentration of silicon crystals, thereby achieving higher performance in chip manufacturing, especially in high-end integrated circuits and high-performance solar cells that require precise electrical property control.

The use of high-purity boron powder can effectively avoid the negative impact of impurities on the performance of silicon ingots during the doping process and improve the electrical, thermal and optical properties of the crystal. Boron-doped silicon materials can provide higher electron mobility, better current-carrying capabilities, and more stable performance when temperature changes, which is critical to the reliability and performance of modern semiconductor devices.

2. Advantages of China’s high-purity crystalline boron powder

As the world's leading producer of semiconductor materials, China has made significant progress in the production technology and quality control of high-purity crystalline boron powder. Domestic companies such as Urban Mining Technology Company have occupied an important position in the global market with their advanced R&D technology and production processes.

Advantage 1: Leading technology and sufficient production capacity

China has continuously innovated in the production technology of high-purity crystalline boron powder, and has a complete production process and strict quality control system. Urban Mining Technology Company adopts the refined production technology independently developed, which can stably produce crystalline boron powder with a purity of more than 6N to meet the high-end needs of the semiconductor industry at home and abroad. The company has made major breakthroughs in the purity, particle size, and dispersibility of boron powder, ensuring that the product can meet the strict requirements of semiconductor manufacturers for high-performance materials.

Advantage 2: Strong cost competitiveness

Due to China's advantages in raw materials, energy and production equipment, the domestic production cost of high-purity crystalline boron powder is relatively low. Compared with the United States, Japan, South Korea and other countries, Chinese companies can offer more competitive prices while ensuring high product quality. This makes China occupy an important position in the global semiconductor industry material supply chain.

Advantage 3: Strong market demand

As China's semiconductor industry continues to grow, local companies' demand for high-purity crystalline boron powder has increased dramatically. China is accelerating the independent control of the semiconductor industry and reducing its dependence on imported high-end materials. Companies such as Urban Mining Technology are actively responding to this trend, expanding production capacity and improving product quality to meet the rapid growth of the domestic market.

3. Current status of the global semiconductor industry

The global semiconductor industry is a highly competitive and technology-intensive industry, with major players including the United States, Japan, South Korea, Europe and other countries and regions. As the basis of semiconductor manufacturing, the quality of silicon ingot production directly determines the performance of subsequent chips. Therefore, the demand for high-purity crystalline boron powder is also increasing.

the United

States has strong silicon ingot production and semiconductor manufacturing capabilities. The US market's demand for high-purity crystalline boron powder is mainly concentrated in the manufacture of high-end chips and integrated circuits. Due to the high price of boron powder produced in the United States, some companies rely on importing high-purity crystalline boron powder from Japan and China.

Japan

has a long-term technical accumulation in the production of high-purity materials, especially in the preparation of boron powder and silicon ingot doping technology. Some high-end semiconductor manufacturers in Japan, especially in the field of high-performance computing chips and optoelectronic devices, have a stable demand for high-purity crystalline boron powder.

South

Korea's semiconductor industry, especially companies such as Samsung and SK hynix, has an important share in the global market. South Korean companies' demand for high-purity crystalline boron powder is mainly concentrated in the fields of memory devices and integrated circuits. South Korea's R&D investment in material technology is also increasing, especially in improving the purity and doping uniformity of boron powder.

4. Future Outlook and Conclusion

With the continuous development of the global semiconductor industry, especially the rapid rise of emerging technologies such as high-performance computing, artificial intelligence, and 5G communications, the demand for high-purity crystalline boron powder will further increase. As an important producer of high-purity crystalline boron powder, Chinese manufacturers have strong competitiveness in technology, quality, and cost. In the future, with further breakthroughs in technology, Chinese companies are expected to occupy a more important position in the global market.

With its strong R&D and production capabilities, UrbanMines Tech. Limited is actively developing domestic and foreign markets to provide stable and reliable high-purity crystalline boron powder products for the global semiconductor industry. As the process of independent control of China's semiconductor industry accelerates, domestically produced high-purity crystalline boron powder will provide a more solid material guarantee for the innovation and development of the global semiconductor industry.

Conclusion

As a key material in the semiconductor industry chain, 6N high-purity crystalline boron powder plays an indispensable role in the production of silicon ingots. Chinese companies are occupying an important position in the global semiconductor materials market with their technological innovation and production advantages. In the future, with the continuous development of semiconductor technology, the market demand for crystalline boron powder will continue to grow, and Chinese high-purity crystalline boron powder manufacturers will continue to promote technological progress and lead the future development direction of the industry.