In recent years, sintered stone has gradually become a popular choice for floor materials due to its excellent performance and beautiful appearance. Whether it is home flooring or commercial space, this new material has shown excellent performance. This article will start from the advantages and disadvantages of sintered stone floor application and explore its value in modern decoration.

Advantages of sintered stone floor tile application

Excellent durability: Sintered stone has extremely high hardness and wear resistance due to its special process. In high-traffic areas (such as commercial centers or airports), the floor can also be kept intact.

Waterproof and anti-fouling: Sintered stone has the characteristics of low water absorption, which is very suitable for use in wet areas such as kitchens and bathrooms. Its surface is dense, stains are not easy to penetrate, and it is very convenient to clean.

Various design options: Sintered stone flooring provides a rich selection of textures and colors, from natural stone textures to modern minimalist styles, which can almost meet various decoration needs. At the same time, sintered stone can be processed into different sizes according to needs to adapt to a variety of space designs.

Environmental protection and health: The production of sintered stone does not use harmful chemicals, does not release harmful gases such as formaldehyde, and conforms to the concept of modern environmentally friendly home. For users who pursue a healthy living environment, sintered stone flooring is an ideal choice.

Heat and frost resistance: Sintered stone can withstand extreme temperature changes, so it is suitable for outdoor flooring, and it can maintain stable performance whether it is hot summer or cold winter.

Disadvantages of sintered stone flooring application

High installation cost: The production and installation process of sintered stone is complicated, and it is more expensive than traditional flooring materials (such as tiles or wooden floors). Therefore, it may need to be carefully considered in decoration projects with limited budgets.

High installation technology requirements: The installation of sintered stone flooring requires a professional team and special tools. If it is not installed properly, it may affect the overall effect and service life of the floor.

Applicable scenarios of sintered stone flooring

Residential decoration: In areas such as living rooms, kitchens, and bathrooms, sintered stone can not only enhance the beauty of the space, but also ensure long-term durability.

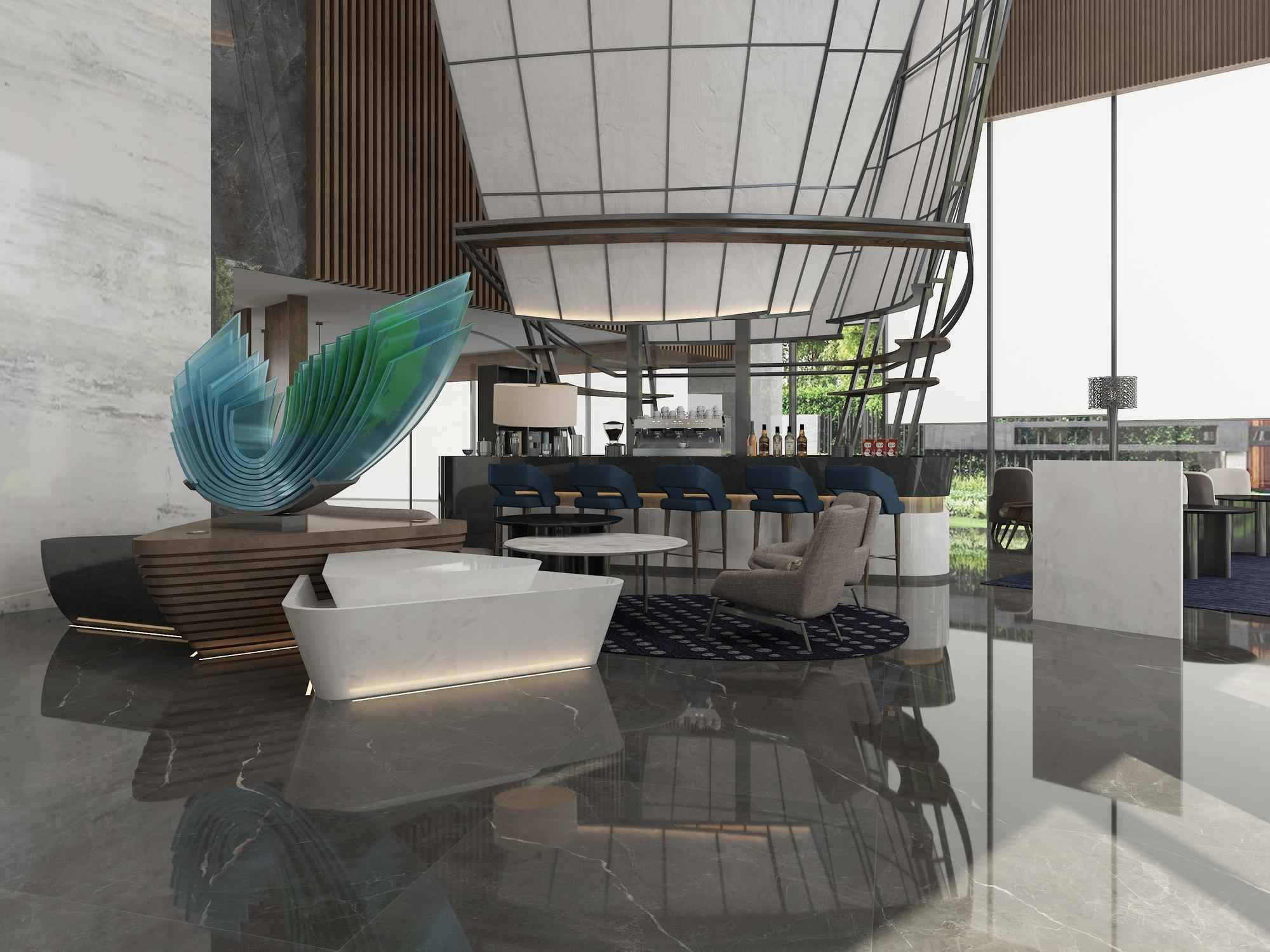

Commercial space: In high-traffic areas such as shopping malls, office buildings, and hotel lobbies, sintered stone floors show superior compression resistance and durability.

How to choose sintered stone flooring

The key to choosing high-quality sintered stone flooring is to find a reliable sintered stone manufacturer. High-quality sintered stone manufacturers usually provide a wider range of design options, higher product quality assurance, and professional after-sales service.

Conclusion

Sintered stone has broad application prospects in the field of floor decoration due to its excellent performance, rich design possibilities and environmental protection characteristics. Although its installation cost and technical requirements are high, for users who pursue high-quality decoration, whether it is residential or commercial space, sintered stone flooring can bring you a super value decoration experience.