When choosing flooring for a home or commercial project, durability is often the most important factor. Property owners, designers, and contractors frequently ask: What kind of flooring lasts the longest? The answer depends on materials, installation quality, maintenance, and the environment where the flooring is used. However, several flooring types consistently stand out for their exceptional lifespan, including porcelain tile, ceramic tile, natural stone, and hardwood. Among these options, tile flooring is widely considered one of the most durable and long-lasting choices available today.

Porcelain Tile: One of the Most Durable Flooring Materials

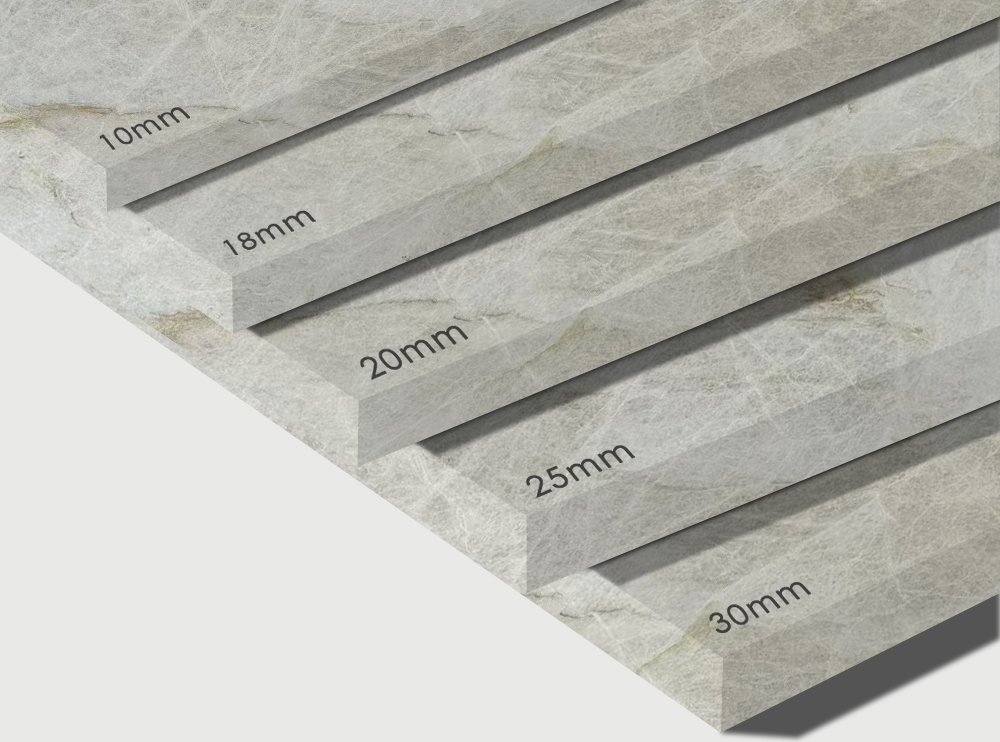

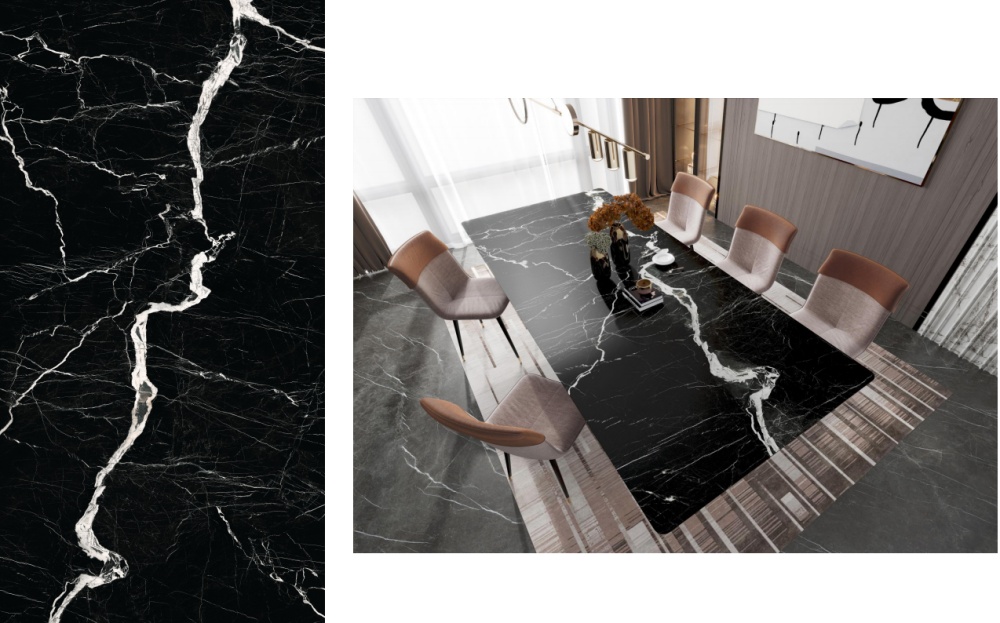

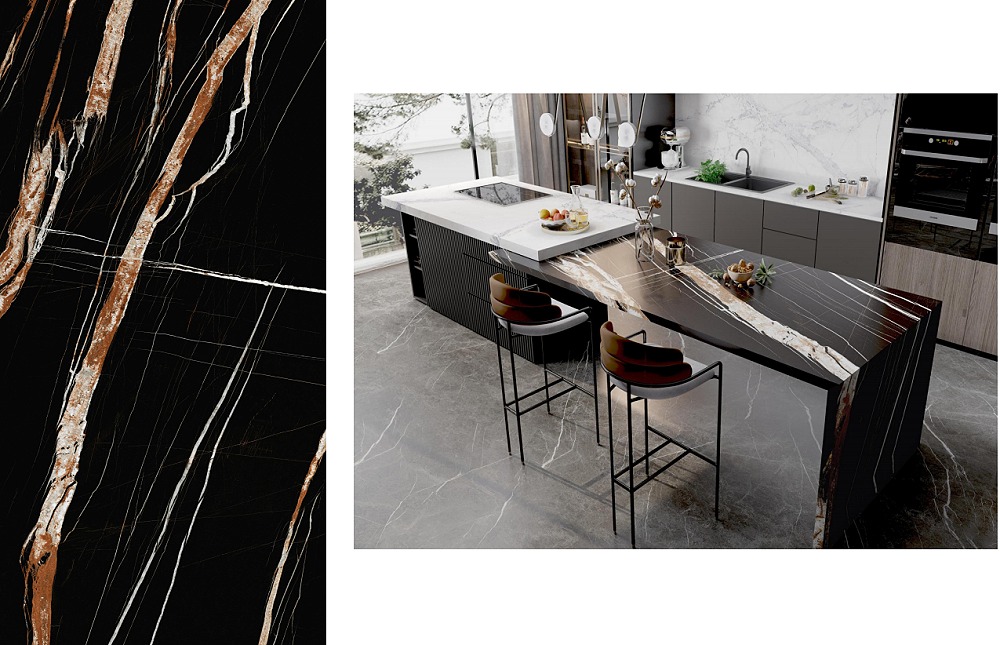

One of the most reliable long-lasting flooring options is porcelain tile flooring. Porcelain tiles are made from refined clay fired at extremely high temperatures, which creates a dense and highly durable structure. Because of this manufacturing process, porcelain floor tiles have very low water absorption and excellent resistance to scratches, stains, and heavy foot traffic.

Many commercial buildings such as shopping malls, hotels, and airports use porcelain tile flooring because it can maintain its appearance for decades. When installed properly, marble look porcelain tile or polished porcelain tile can easily last 50 years or more with minimal maintenance. This makes porcelain tile one of the most cost-effective flooring solutions in the long run.

Another advantage of large format porcelain tile is its versatility. It can be used for living rooms, kitchens, bathrooms, hotel lobbies, and even large commercial spaces. The combination of durability, elegant appearance, and easy cleaning makes porcelain tiles a preferred choice for both residential and commercial applications.

Ceramic Tile: A Long-Lasting and Affordable Option

Another popular and durable option is ceramic tile flooring. Ceramic tiles are also made from clay and fired in a kiln, though usually at slightly lower temperatures than porcelain. As a result, ceramic floor tiles are generally more affordable while still providing excellent durability.

In many homes, ceramic tile floor installations have lasted for several decades without needing replacement. Modern manufacturing technology also allows ceramic tiles to replicate the look of natural materials such as stone and marble. For example, marble look ceramic tile provides the luxury appearance of marble while offering easier maintenance and better resistance to stains.

Because of its durability and versatility, ceramic tile flooring is commonly used in kitchens, bathrooms, corridors, and indoor living spaces. When properly maintained, ceramic tile floors can last 30–50 years or even longer.

Natural Stone Flooring

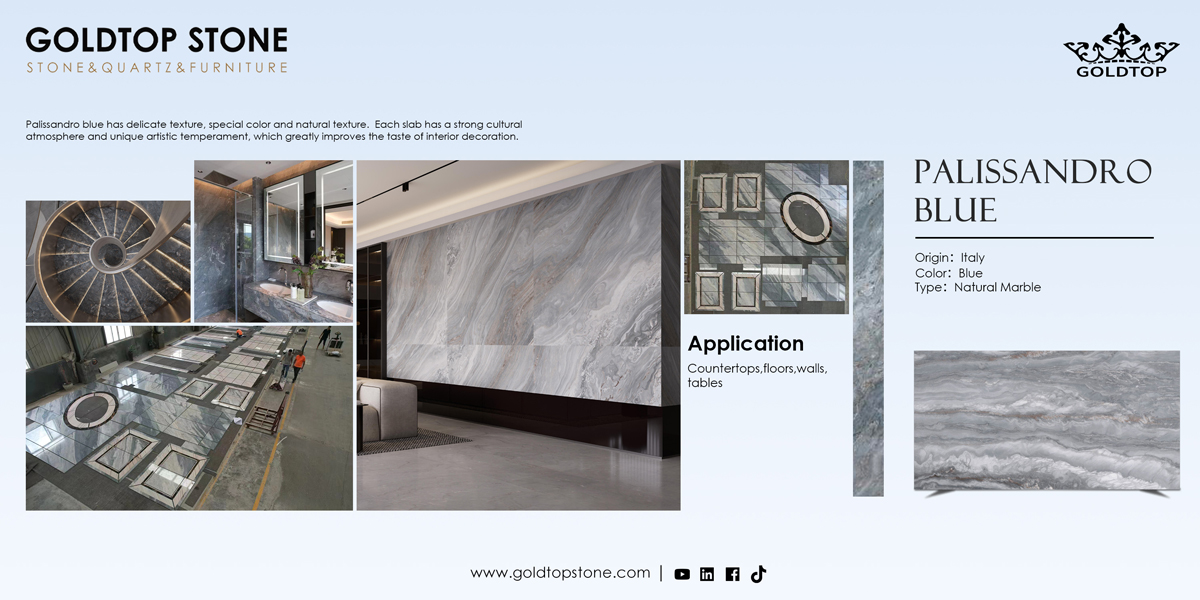

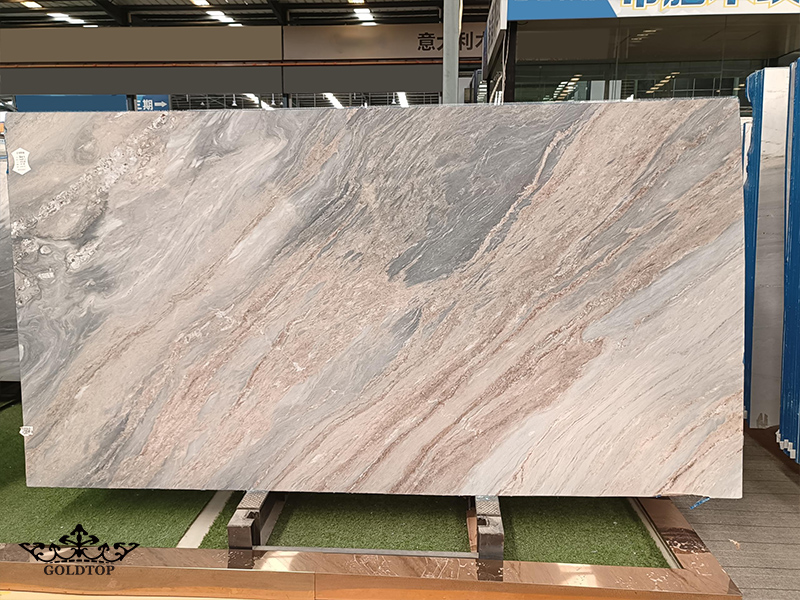

Natural stone flooring such as granite, marble, and slate is also known for its longevity. Materials like granite are extremely hard and can last for generations. However, natural stone usually requires more maintenance, including sealing and careful cleaning, to preserve its appearance.

In addition, natural stone flooring tends to be more expensive than tile alternatives. For many homeowners and developers, porcelain tile that replicates stone textures offers a practical balance between durability, aesthetics, and cost.

Hardwood Flooring

Hardwood flooring is another long-lasting option that can remain in good condition for many decades. High-quality hardwood floors can be sanded and refinished multiple times, extending their lifespan significantly. However, hardwood is more sensitive to moisture, scratches, and heavy traffic compared with tile flooring.

Because of these limitations, hardwood is often used in living rooms and bedrooms rather than bathrooms or kitchens.

Why Tile Flooring Often Lasts the Longest

Among all flooring materials, tile—especially porcelain tile flooring—offers a unique combination of strength, stability, and low maintenance. High-quality porcelain floor tiles resist moisture, scratches, and wear better than many other flooring materials. They also maintain their color and texture for decades without fading.

Additionally, modern manufacturing technologies allow tiles to reproduce natural surfaces such as marble, stone, and concrete. Options like marble look porcelain tile, polished porcelain tile, and large format porcelain tile provide both durability and premium aesthetics.

For homeowners, architects, and developers looking for a long-lasting flooring solution, tile flooring remains one of the most reliable investments.

Conclusion

If longevity is the main priority, porcelain tile flooring is widely considered one of the longest-lasting flooring materials available. Ceramic tile flooring also provides excellent durability at a more affordable price. While natural stone and hardwood can also last for many years, tile flooring stands out because of its resistance to moisture, scratches, and heavy traffic.

By choosing high-quality porcelain floor tiles or ceramic floor tiles, property owners can enjoy beautiful and durable flooring that lasts for decades.