Introduction

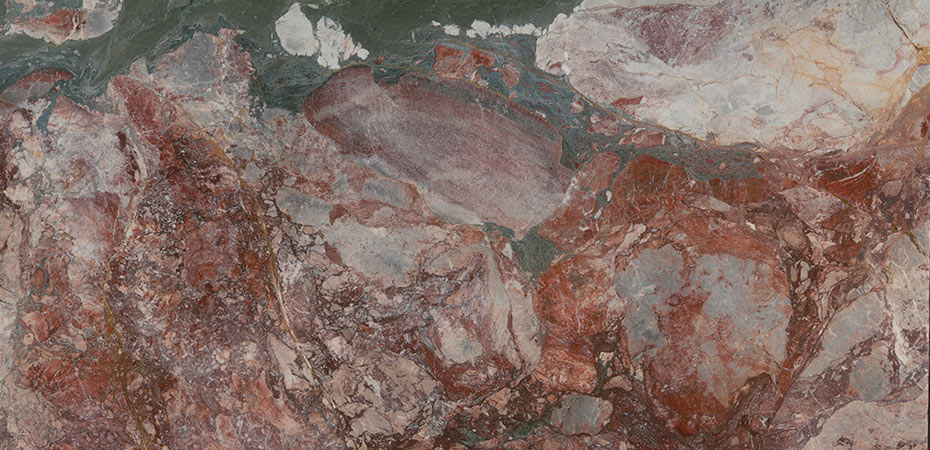

When functionality meets luxury, few materials can rival the stunning Blue Labradorite Granite. Known for its mesmerizing iridescence and unmatched durability, this granite type is becoming an increasingly popular choice for high-end kitchen countertops in residential and commercial projects worldwide.

At GOLDTOP STONE, we proudly offer top-tier Blue Labradorite Granite kitchen countertops for global B2B buyers, interior designers, builders, and distributors looking to deliver both aesthetic appeal and lasting performance to their clients.

Product Features & Advantages

Unique Iridescence

Blue Labradorite is famous for its vibrant flashes of blue, green, and silver—natural optical phenomena known as labradorescence. Every slab is a piece of art formed by nature.

Durability & Performance

This granite is exceptionally hard and resistant to heat, scratches, and stains. It performs well in both residential and commercial kitchens.

Low Maintenance

Sealed surfaces are easy to clean and maintain, making it ideal for busy food-prep areas.

Premium Appeal

Its exotic look instantly elevates the status of any interior space, making it a favorite for luxury real estate, hotels, and upscale showrooms.

Custom Sizes & Edge Profiles

Available in multiple thicknesses and customizable edge profiles to suit various installation requirements.

Applications

Blue Labradorite Granite is ideal for:

Kitchen countertops in luxury homes and villas

Bar counters in boutique hotels or high-end restaurants

Reception desks in modern office spaces

Vanity tops and islands in residential or commercial interiors

Wall cladding or feature panels for an eye-catching statement

Why Choose GOLDTOP STONE

With 20+ years of experience in natural stone fabrication and export, we specialize in high-grade stone products tailored for overseas markets. Our Blue Labradorite Granite slabs undergo strict quality checks and are securely packed for international shipping.

Support for OEM/ODM

Bulk supply and custom packaging

Fast response for international inquiries

Visit us or book a virtual factory tour